Address: Lianxi Boulevard(M. Section), Jiujiang, Jiangxi, China

Phone: 0792-8352828

0792-8352066

Fax: 0792-8352666

Mail: jjyixin@jjyixin.cn

URL: www.jx-yixin.com

Website:www.canmakingmachine.net

Application of tin sealing machine in beer production line

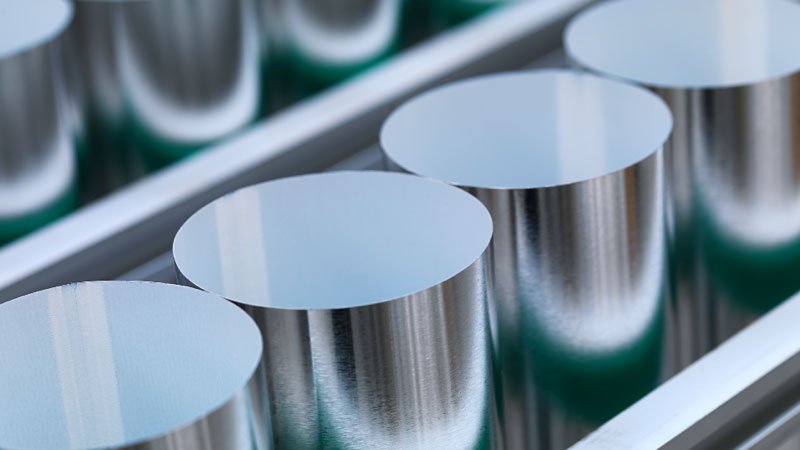

The packaging of beer is simpler and easier to control than bottling and bottling. The main equipment of an automatic dressing line is composed of unloading machine, tank wine - roll machine, sterilizer, packing machine / sealing machine, filling speed can reach 1000cpm, and listen to the factory cans comparable.

Beer canned process: Sealer to the code layer of empty cans from the plastic tray unloaded, pushed to the plastic chain plate, into the washing machine with 80 ℃ hot water rinse, dry, to aseptic. And then use CO2 isostatic filling, the use of carbon dioxide to replace the tank air, canned, sprayed with carbon dioxide foam to the mouth, quickly cover. The automatic level meter is used to detect the liquid level, followed by pasteurization (spray sterilization).

The jar after filling is blown by the air dryer and then sprayed on the bottom of the tank for production. According to the packaging form, the use of different packing machine: single-chip die-cutting cardboard is a wrapping type, listen to the child pressure to a large surface of the cardboard, mechanical bar in turn will be another large and two sides raised, Sol fast bonding manufacturer seam and shaking lid. Wrapping type widely used in the domestic brewery, packing machine sucker will be a large adsorption of hollow, mechanical rods into the hearing inward, and then bonding, this packing method is very efficient, widely used abroad. Wrapping machine can also be wrapped with a paper tray tray of the thermoplastic film box, this time the packing machine needs to be equipped with a PE film cutting, wrapping system and heat shrinkable furnace. If the PE film surface printing, you need to configure the optical eye device. After automatic packing, the box is no longer used OPP sealing tape. A typical 355ml canvas is 24 cans, and there are 18 and 12 cans, depending on the custom of the consumer's full box purchase.

Modern beer technology Widely used computer identification system and digital display instrument to help mechanized filling operation, to ensure that the quality of beer in the filling process is not affected. Sealing machine can automatically detect the following cans manufacturing defects: oil, liquid, deformation, foreign body, and odor, the unqualified containers removed from the line.

Yixin Machinery can provide the complete tin can making machine of all kinds of metal cans. The hotline: 0086-792-8358866